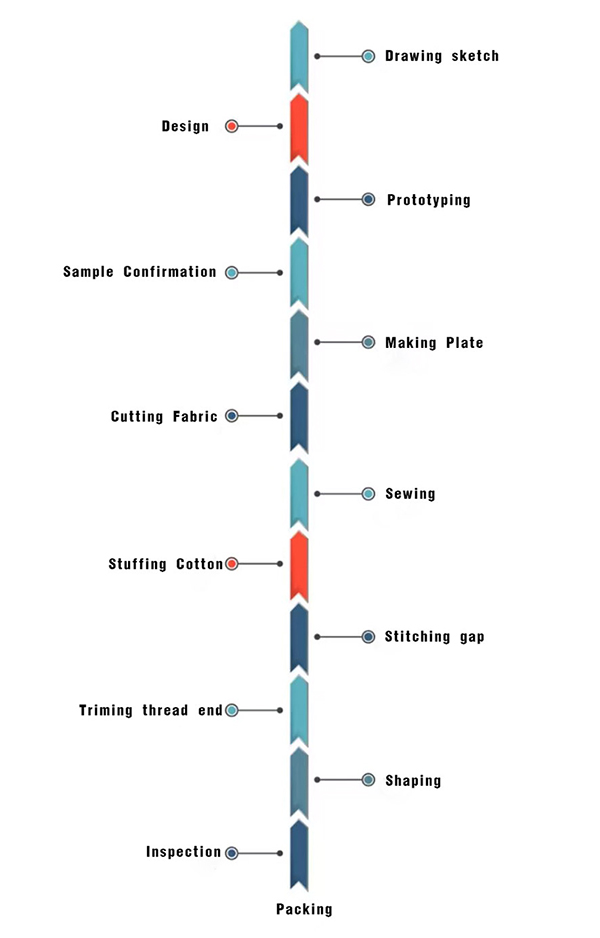

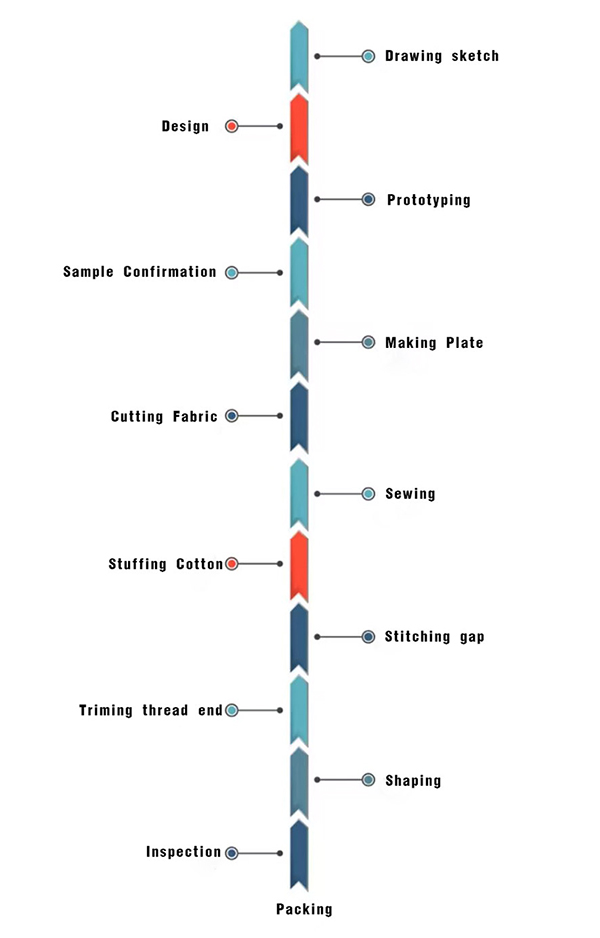

The Process Of Manufacturing Plush toys

Stuffed animals and plush toys are very popular among children and parents, they can not reject to touch the soft fluffy skin. They work as a comfort to soothe them into sleep, a friend when they need one and they often are carried throughout childhood. Some even hold on to the toys in adulthood as keepsakes and precious memories. Both boys and girls love soft skin-friendly stuffed animals&plush toys.

The craftsmanship is not complicated. There are basically 8 steps to make mass production of plush toys. Although it is the main production process, owing to different production capacity in practical production, some workshops will skip these below one or more steps, outsourcing the work for saving time and labor costs.

1.Design Stuffed animals and plush toys

In the beginning, you need to decide what toy you want to create. Design the shape of the plush toy as you are brainstorming from collective suggestions or from your client’s demand. Some classic cartoon patterns are original from the artists ‘ creations.

Draw your pattern, mark its outline by the contour tool, ensure that you only have the outline of your shape selected. Cut it along the edges. Finally, you need to transfer the pattern into the fabric.To create a original plated require good handwork,Bunnyhello’s supplier team have more than 20 years experience in customsize your plush toys.

2.Cutting Fabrics

Cutting fabrics into small slices after the manufacturer outsourced the plush materials, and finish the heat treatment process. Most workshops had imported laser cutting machines, it will be automatically slicing the whole fabric into the animal shape or others they need.

3.Embroidery

Embroidery the fabric with a pattern that meets the design demand, it can easily and efficiently by the computer embroidery machine. Some patterns need to be printed. The stuffed animals vary in design. This requires craftsmanship that can be quickly adjusted.

4.Sewing

The sewing process costs so many working hours in all steps, it needs to stitch the fabrics evenly, Workers need to sew the fabrics carefully and skillfully. In this step, irregular pieces will be combined into a basic model. Later, the accessories such as buckles, labels, droplets also were stitched into plush toys. To make a simple stuffed toy, there are two pieces of sewing fabric, one is a front, another is a back, Usually, After you’ve stuffed your animal, you’ll sew up the small hole you used to put in the stuffing.

5.Filling

Filling the synthetic fiber into plush toys. Put the sewed toy onto the filling shaft axle. Press down the valve, Release the valve until the stuffed animal toys become fluffy. You should put the stuffing as much as you can. The basic workmanship of stuffed toys comes to the end.

6.Stitching/Close up fabric

After stuffing cotton into toys, there was left a small gap, Sew them down till the edge to close up the gap tightly. Trim any excess threads. The finished products had been made perfectly.

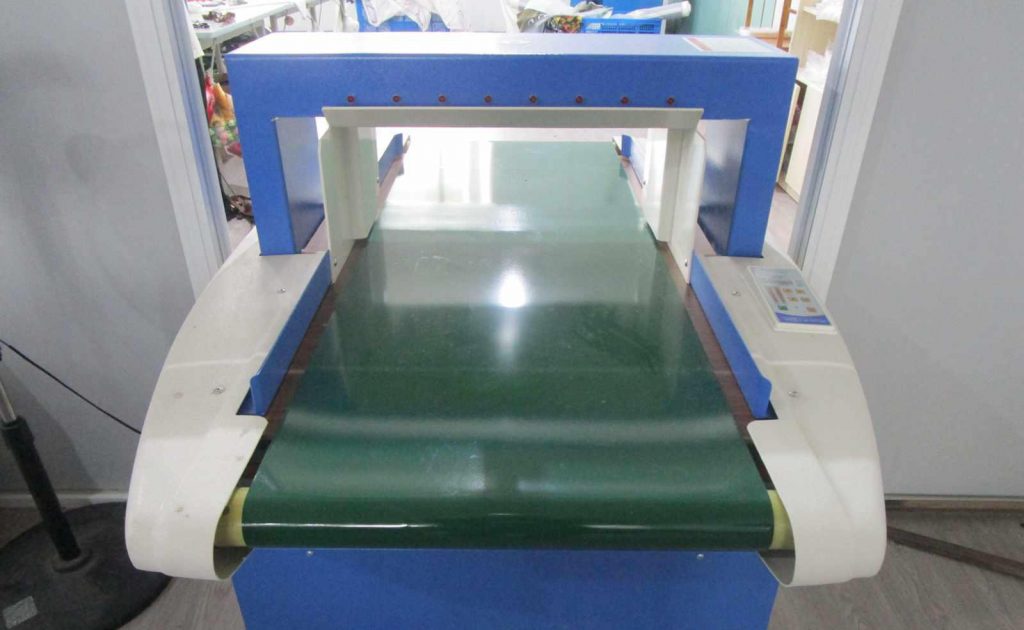

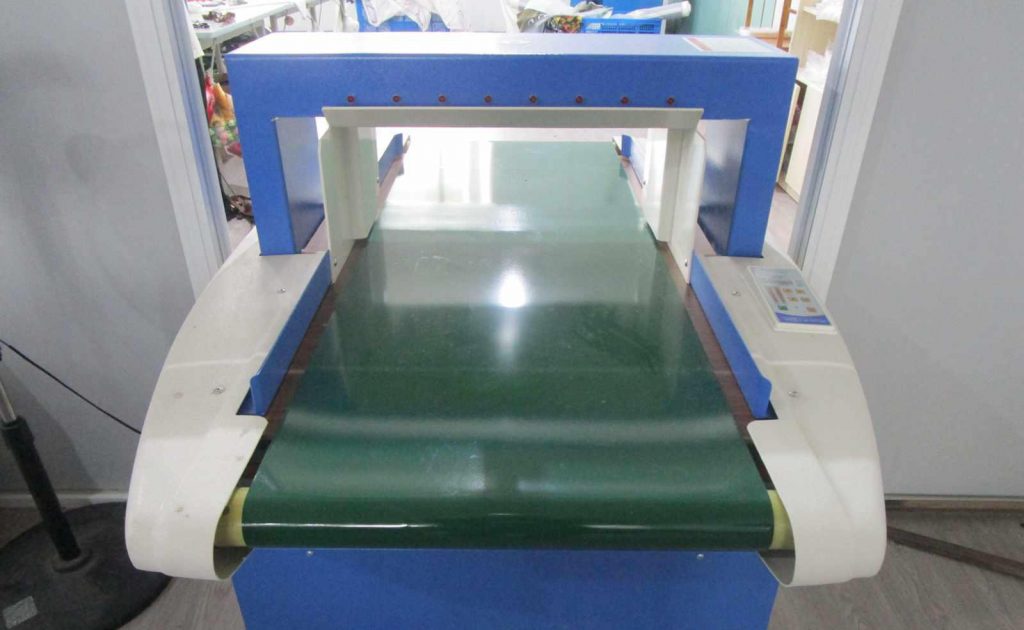

7.Quality Inspection

After mass production, the final step requires quality inspection, normally, visual inspect the appearance, check whether there are defects above process, check if the products are good or not, The factory use the metal detector for quality inspection to avoid dropping off small things. It prevents the younger children from swallowing the parts accidentally.

8.Packing

The work process reaches the last step of packing the finished plush toy. Each stuffed toy with a transparent plastic bag that is waterproof. Some products are required to be vacuum compacted. All the finished stuffed toys will be put into cartons with the printed mark for shipment.

Generally, making stuffed animals and plush toys contain design, cutting slices, sewing, embroidery, stitching, filling, inspection, packing. Nevertheless, the main manufacturer focus on following the whole supply chain, subcontract therein works in peak season. This is flexible and more efficient to meet the change of marketplace.